In the mold manufacturing process, the forming parts of the mold often need to be surface polished. Mastering the polishing technology can improve the quality and service life of the mold, and then improve the product quality.

1. Mold polishing method and working principle

Mold polishing usually uses oil stone strips, wool wheels, sandpaper, etc. to make the surface of the material plastically deform and remove the protrusions on the surface of the workpiece to obtain a smooth surface. Generally, manual operations are the main method. If the surface quality is high, the method of ultra-fine grinding and polishing can be adopted. The ultra-fine grinding and polishing uses a special abrasive tool, which is pressed tightly on the surface of the workpiece to be processed in the polishing liquid containing abrasives for high-speed rotation. Polishing can reach a surface roughness of Ra0.008 μm.

2. Commonly used tools and specifications for mold polishing

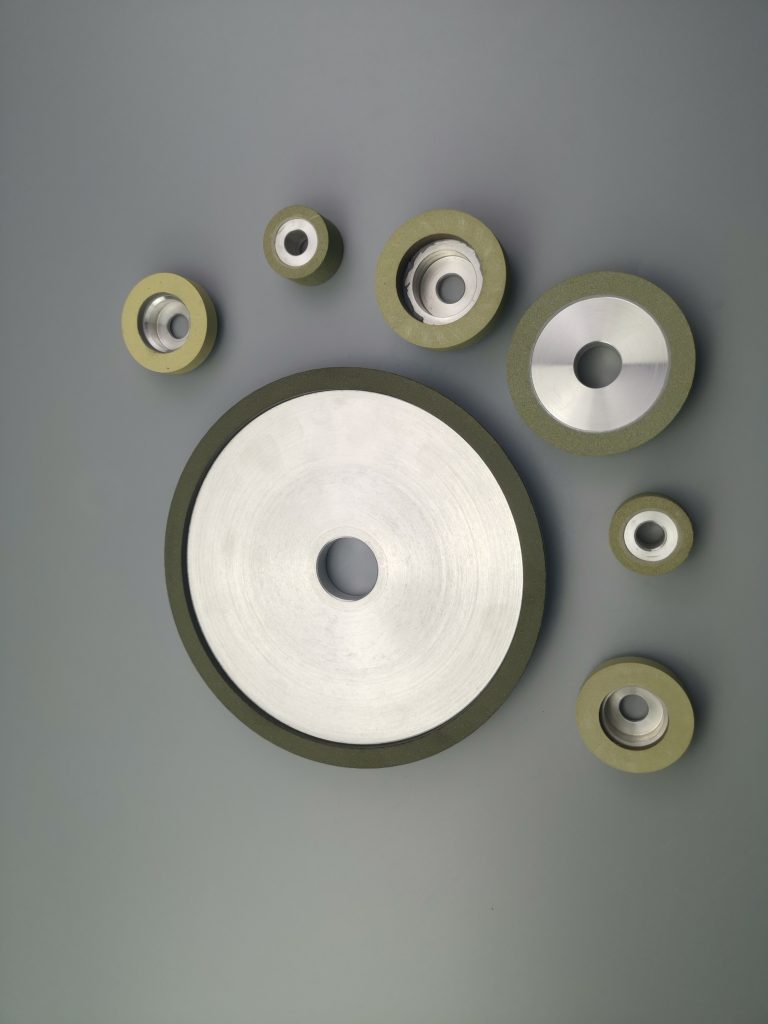

1) The commonly used tools for mold polishing are: sandpaper, oil stone, felt wheel, abrasive paste, alloy file, diamond grinding needle, bamboo chip, fiber oil stone, and circular grinding machine.

2) Sandpaper: 150#, 180#, 320#, 400#, 600#, 800#, 1 000#, 1 200#, 1 500#;

3) Whetstone: 120#, 220#, 400#, 600#;

4) Tape wheel: cylindrical, conical, square tip;

5) Grinding paste: 1# (white) 3# (yellow) 6# (orange) 9# (green) 15# (blue) 25# (brown) 35# (red) 60# (purple);

6) Files: square, round, flat, triangular and other shapes;

7) Diamond grinding needle: generally 3/32 shank or 1/8 shank, with round wave shape, cylindrical shape, long straight column shape, long circular cone shape;

8) Bamboo slices: Various shapes are suitable for the operator and the shape of the mold. The function is to press the sandpaper and grind on the workpiece to achieve the required surface roughness;

9) Fiber oil stone: 200# (black) 400# (blue) 600# (white) 800# (red)

3. Polishing process

rough throw

The surface after fine milling, EDM, grinding and other processes can be polished by a rotary surface polishing machine with a speed of 35 000 to 40 000 r/min. Then manual whetstone grinding, strip whetstone plus kerosene as lubricant or coolant. The order of use is 180#→240#→320#→400#→600#→800#→1 000#.

Semi-fine polishing

Semi-fine polishing mainly uses sandpaper and kerosene. The number of sandpaper is as follows: 400#→600#→800#→1000#→1200#→1500#. In fact, #1500 sandpaper is only suitable for hardened mold steel (above 52HRC), not for pre-hardened steel, because it may cause surface damage of pre-hardened steel parts, and the expected polishing effect cannot be achieved.

fine polishing

Fine polishing mainly uses diamond abrasive paste. If the polishing cloth wheel is mixed with diamond grinding powder or grinding paste for grinding, the usual grinding sequence is 9 μm (1 800#) → 6 μm (3 000#) → 3 μm (8 000#). 9 μm diamond abrasive paste and polishing cloth wheel can be used to remove hair-like wear marks left by 1 200# and 1 500# sandpaper. Then polish with sticky felt and diamond abrasive paste, the order is 1 μm (14 000#) → 1/2 μm (60 000#) → 1/4 μm (100 000#).

4. Working environment for mold polishing

The polishing process should be completed in two separate work locations, that is, the rough grinding processing location and the fine polishing processing location are separated, and attention should be paid to cleaning the sand remaining on the surface of the workpiece from the previous process.

Generally, after rough polishing with oilstone to 1200# sandpaper, the workpiece needs to be transferred to a clean room for polishing to ensure that no dust particles in the air stick to the surface of the mold. The polishing process whose precision is required to be above 1 μm (including 1 μm) can be carried out in a clean polishing room. For more precise polishing, it must be in an absolutely clean space, because dust, smoke, dandruff and saliva may scrap the high-precision polished surface.

After the polishing process is completed, the surface of the workpiece should be protected against dust. When the polishing process is stopped, all abrasives and lubricants should be carefully removed to ensure that the surface of the workpiece is clean, and then a layer of mold anti-rust coating should be sprayed on the surface of the workpiece.

5. Factors affecting mold surface polishability

Workpiece Surface Condition

During the machining process of materials, the surface layer will be damaged due to heat, internal stress or other factors, and improper cutting parameters will affect the polishing effect. The surface after EDM is more difficult to grind than the surface after machining or heat treatment, so EDM finishing should be used before the end of EDM, otherwise the surface will form a hardened thin layer. If the EDM specification is not properly selected, the depth of the heat-affected layer can reach up to 0.4 mm. The hardened thin layer is harder than the substrate and must be removed. Therefore, it is best to add a rough grinding process to provide a good basis for polishing.

Steel quality

High-quality steel is a prerequisite for good polishing quality, and various inclusions and pores in steel will affect the polishing effect. To achieve a good polishing effect, the workpiece must be marked with the surface roughness of the polishing at the beginning of machining. When a workpiece is determined to require mirror polishing, it is necessary to choose steel with good polishing performance and all have been heat-treated, otherwise it will not be achieved.

heat treatment process

If the heat treatment is not proper, the steel surface has uneven hardness or differences in properties, which will cause difficulties in polishing.

polishing technique

Since polishing is mainly done manually, human skills are still the main reason affecting the quality of polishing.

It is generally believed that the polishing technology affects the surface roughness. In fact, good polishing technology needs to be combined with high-quality steel and correct heat treatment process to obtain a satisfactory polishing effect; on the contrary, if the polishing technology is not good, no matter how good the steel is, the mirror effect cannot be achieved.

6. Matters needing attention in different types of polishing

Matters needing attention in mold sandpaper grinding and oilstone grinding

1) For the mold surface with high hardness, only clean and soft oilstone can be used to polish the tools.

2) When changing the sand grade during grinding, the hands of the workpiece and the operator must be cleaned to avoid bringing the coarse sand to the next finer grinding operation.

3) When performing each grinding process, the sandpaper should be polished from different 45° directions until the upper-level sand grains are eliminated. When the upper-level sand grains are removed, the sanding time must be extended by 25% before It can be converted to the next finer sand number.

4) Changing different directions during grinding can avoid unevenness such as waves on the workpiece.

Matters needing attention in diamond grinding and polishing

Diamond grinding and polishing must be carried out under light pressure as much as possible, especially when polishing pre-hardened steel parts and polishing with fine abrasive pastes. When polishing with 8 000# abrasive paste, the common load is 100-200 g/cm2, but it is difficult to maintain the accuracy of this load. To make this easier, make a thin, narrow handle out of the wooden strip, or cut a section out of the bamboo strip to make it more flexible. This helps to control the polishing pressure to ensure that the mold surface pressure is not too high. When grinding and polishing with diamonds, not only the working surface is required to be clean, but also the worker’s hands must be very clean.

Matters needing attention in plastic mold polishing

The polishing of plastic molds is very different from the surface polishing required in other industries. Strictly speaking, the polishing of plastic molds should be called mirror processing. It not only has high requirements on the polishing itself but also has high standards on surface flatness, smoothness and geometric accuracy.

The standard of mirror polishing is divided into 4 levels:

A0=Ra0.008 μm

A1=Ra0.016 μm

A3=Ra0.032 μm

A4=Ra0.063 μm

Because electrolytic polishing, fluid polishing and other methods are difficult to accurately control the geometric accuracy of parts, and the surface quality of chemical polishing, ultrasonic polishing, magnetic abrasive polishing and other methods cannot meet the requirements, so the mirror processing of precision molds is still based on mechanical polishing host.

The precautions in polishing are as follows:

1) When starting to process a new mold cavity, check the surface of the workpiece first, and clean the surface with kerosene so that the oilstone surface will not stick to dirt and lose the cutting function.

2) When grinding coarse grains, it should be done in the order of difficulty first and then easy, especially for some dead corners that are difficult to grind, the deeper bottom should be grinded first, and the sides and large planes should be grinded last.

3) Some workpieces may be grinded together in groups of multiple pieces. The rough grain or fire pattern of a single workpiece should be grinded separately, and then all the workpieces should be grinded together until smooth.

4) For workpieces with large flat or side planes, use oilstone to grind away rough grains and then use a straight steel sheet for light transmission inspection to check whether there is any unevenness or undercut. If there is undercut, it will cause the workpiece Difficulty demolding or parts strained.

5) In order to prevent the mold workpiece from being buckled or some bonding surfaces need to be protected, it can be pasted with a saw blade or pasted on the edge with sandpaper, so that an ideal protection effect can be obtained.

6) Pull back and forth to grind the plane of the mold, and pull the handle of the oil stone as flat as possible, and do not exceed 25°. Because the slope is too large, the force is punched from top to bottom, and it is easy to grind a lot of rough lines on the workpiece.

7) If the plane of the workpiece is polished with copper or bamboo sheets pressed against sandpaper, the sandpaper should not be larger than the area of the tool, otherwise it will grind into places that should not be ground.

8) Try not to use a grinder to repair the parting surface, because the parting surface repaired by the grinding wheel head is rough and has waves and unevenness. If necessary, the grinding wheel head must be glued to the concentricity balance.

9) The shape of the grinding tool should be close to the surface shape of the mold, so as to ensure that the workpiece will not be ground and deformed.

7. How to solve common problems in polishing

over polished

The biggest problem encountered in the daily polishing process is “over-polishing”, which means that the longer the polishing time, the worse the quality of the mold surface. There are two phenomena of excessive polishing: “orange peel” and “pitting”. Excessive polishing often occurs in mechanical polishing.

Causes of “orange peel” on workpieces

The irregular and rough surface is called “orange peel”. There are many reasons for “orange peel”. The most common reason is that the surface of the mold is overheated or carburized. The main cause of “orange peel”. For example: buffing wheel polishing, the heat generated by the buffing wheel can easily cause “orange peel”. Harder steel can withstand greater polishing pressure, and relatively soft steel is prone to over-polishing. Studies have shown that the time for over-polishing will vary depending on the hardness of the steel.

Measures to Eliminate “Orange Peel” of Workpieces

When it is found that the surface quality is not well polished, many people will increase the polishing pressure and prolong the polishing time, which will often make the surface quality worse.

The following methods can be used to remedy:

1) Remove the defective surface, the grinding grain size is slightly coarser than the previously used sand number, and then grind, the polishing intensity is lower than the previous one.

2) Stress relief is carried out at a temperature lower than the tempering temperature of 25 ℃, and the finest sand number is used for grinding before polishing until a satisfactory effect is achieved, and finally polished with a lighter force.

Reasons for the formation of “pitting corrosion” on the surface of the workpiece

Since there are some non-metallic impurities in the steel, usually hard and brittle oxides, they are pulled out from the steel surface during the polishing process, forming micro pits or pitting corrosion. The main factors of “pitting corrosion” are as follows:

1) The polishing pressure is too high and the polishing time is too long.

2) The purity of the steel is not enough, and the content of hard impurities is high.

3) The surface of the mold is rusted.

4) The black leather is not removed.

Measures to Eliminate Pitting Corrosion of Workpiece

1) Carefully regrind the surface. The grain size of the sand is slightly coarser than that used before. Use a soft and sharpened whetstone for the final grinding step before proceeding to the polishing process.

2) The softest polishing tools should be avoided when the grit size is less than 1 mm.

3) Use the shortest polishing time and the smallest polishing force as possible.

The polishing of the cavity in the mold manufacturing process is a very important process. It is related to the quality and life of the mold, and also determines the quality of the product. Mastering the working principle and process of polishing and choosing a reasonable polishing method can improve the quality and life of the mold, thereby improving the quality of the product.