Operating Specifications for Aluminum Profile Chassis Casing: Aluminum Alloy CNC Processing

Introduction:

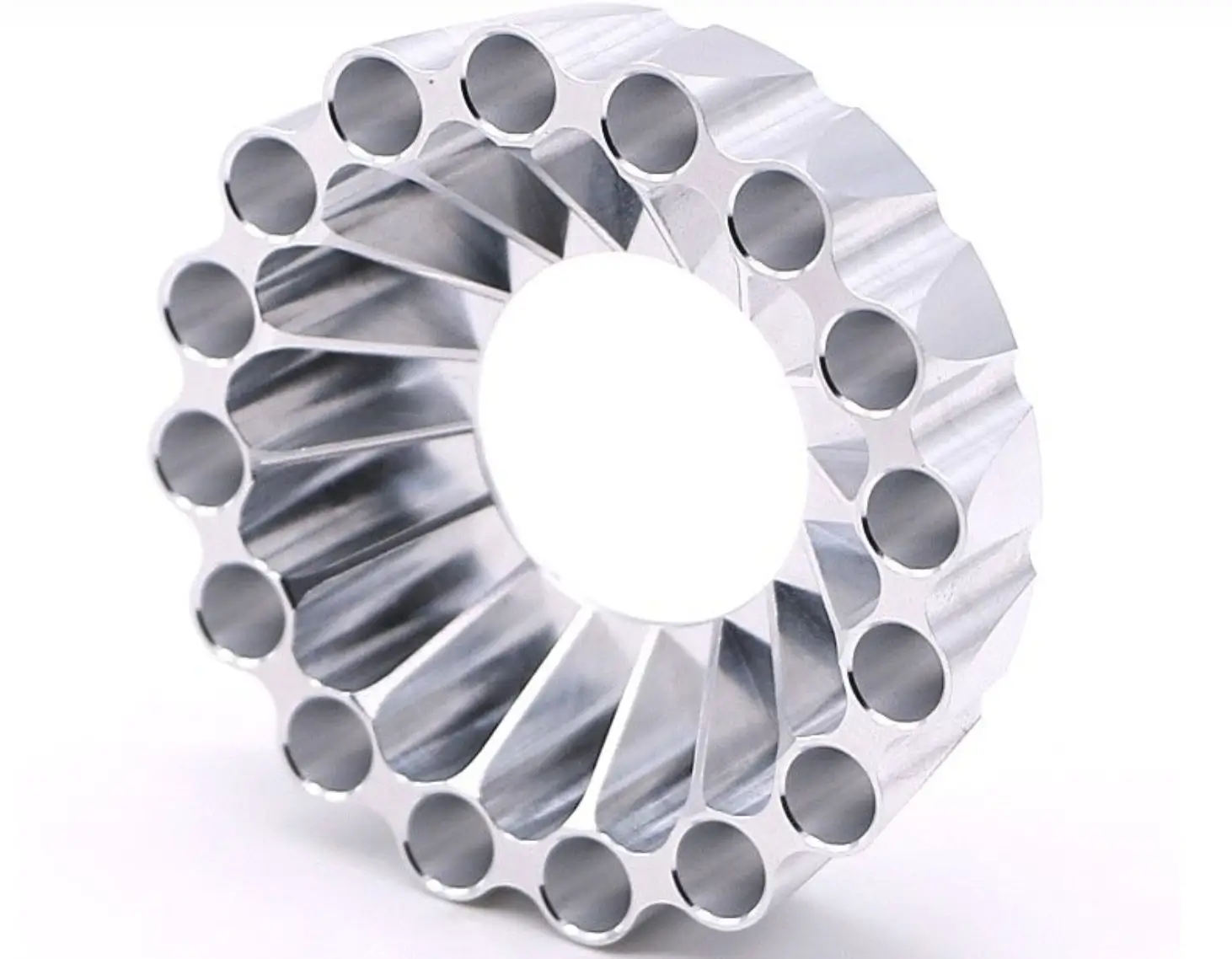

Aluminum profile chassis casings are widely used in various industries due to their lightweight, high strength, and corrosion resistance properties. To ensure the quality and precision of these casings, aluminum alloy CNC processing is commonly employed. This article provides a comprehensive guide on the operating specifications for aluminum profile chassis casing production using aluminum alloy CNC processing.

1. Material Selection:

When selecting materials for aluminum profile chassis casings, it is crucial to choose high-quality aluminum alloys that meet specific requirements such as hardness, strength, and corrosion resistance. The commonly used aluminum alloys for chassis casings include 6061 and 6063. These alloys offer excellent machinability and are suitable for CNC processing.

2. CAD Design and Programming:

Before initiating the CNC machining process, it is essential to create a precise computer-aided design (CAD) model of the desired aluminum profile chassis casing. The CAD model serves as a reference for the CNC machine to execute the machining operations accurately. Additionally, the CAD model assists in programming the CNC software, allowing for efficient and effective machining.

3. Fixturing and Clamping:

Proper fixturing and clamping of the aluminum profiles are crucial to maintain stability during CNC processing. Special attention should be given to ensure that the profiles are securely held in place to avoid any movement or vibration during machining. Precision fixtures and clamps should be used to ensure accurate and repeatable results.

4. Cutting Parameters:

The selection of appropriate cutting parameters, such as spindle speed, feed rate, and depth of cut, is essential to achieve optimal results during aluminum alloy CNC processing. It is recommended to start with conservative values and gradually increase the cutting parameters to find the optimal balance between machining efficiency and surface quality. Regular monitoring and adjustment of cutting parameters are necessary to accommodate variations in material properties and machining conditions.

5. Tooling Selection:

Selecting the right tools is critical for aluminum alloy CNC processing. Carbide or high-speed steel (HSS) tools are commonly used due to their excellent cutting performance and durability. The selection of appropriate cutting tools depends on various factors, including the desired surface finish, machining operations, and material hardness. Regular tool inspection and replacement are necessary to maintain machining accuracy and minimize tool wear.

6. Cooling and Lubrication:

During aluminum alloy CNC processing, adequate cooling and lubrication are essential to dissipate heat generated during machining and reduce friction between the cutting tool and workpiece. A water-soluble coolant or cutting oil should be applied generously to prevent tool overheating, prolong tool life, and improve surface finish. Proper chip evacuation is also crucial to avoid chip buildup and potential damage to the workpiece and cutting tools.

7. Quality Control:

To ensure the quality of aluminum profile chassis casings produced through aluminum alloy CNC processing, regular quality control checks should be conducted. This includes dimensional measurements using precision measuring tools, visual inspection for surface defects, and stress testing to ensure structural integrity. Non-destructive testing techniques, such as ultrasonic or X-ray inspection, can be employed for additional quality assurance.

Conclusion:

Operating specifications play a vital role in achieving high-quality aluminum profile chassis casings through aluminum alloy CNC processing. By following these guidelines, manufacturers can optimize production efficiency, minimize errors, and deliver reliable and durable casings to meet industry demands. Continuous improvement and adherence to these specifications will contribute to the overall success of aluminum profile chassis casing production.

.webp)