CNC Processing of Aluminum Profiles: Advantages and Processing Methods

Introduction:

CNC (Computer Numerical Control) processing has revolutionized the manufacturing industry by offering precise and efficient methods for processing various materials. In the case of aluminum profiles, CNC processing has become increasingly popular due to its numerous advantages. This article aims to explore the main advantages of CNC processing for aluminum profiles and discuss the different processing methods used in this field.

Advantages of CNC Processing for Aluminum Profiles:

1. Precision: One of the key advantages of CNC processing is its ability to achieve high precision. Computer-controlled machines can perform intricate cuts, holes, and shape profiles with exceptional accuracy, ensuring a perfect fit and eliminating errors caused by manual processes. This precision is crucial for industries such as aerospace, automotive, and electronics, where tight tolerances are required.

2. Efficiency: CNC processing offers remarkable efficiency compared to traditional machining methods. Once the machine is programmed, it can run autonomously, reducing the need for manual labor and minimizing human error. Additionally, CNC machines can operate at high speeds, enabling faster production rates and shorter lead times, which is beneficial for meeting tight deadlines and customer demands.

3. Versatility: CNC machines are versatile and can handle a wide range of aluminum profile processing tasks. They can perform milling, drilling, tapping, cutting, and other operations with ease, allowing manufacturers to create complex and customized profiles. This versatility opens up possibilities for product innovation and design flexibility.

4. Consistency: With CNC processing, manufacturers can achieve consistent results across multiple batches or products. The computer-controlled machines follow pre-programmed instructions precisely, ensuring that each aluminum profile produced is identical in terms of dimensions, shape, and quality. This consistency is essential for maintaining product standards and meeting customer specifications consistently.

5. Waste Reduction: CNC processing minimizes material waste significantly. The machines can optimize the cutting path and make use of the material efficiently, resulting in minimal scrap and increased material utilization. This waste reduction not only contributes to cost savings for manufacturers but also aligns with sustainable manufacturing practices.

Processing Methods for CNC Processing of Aluminum Profiles:

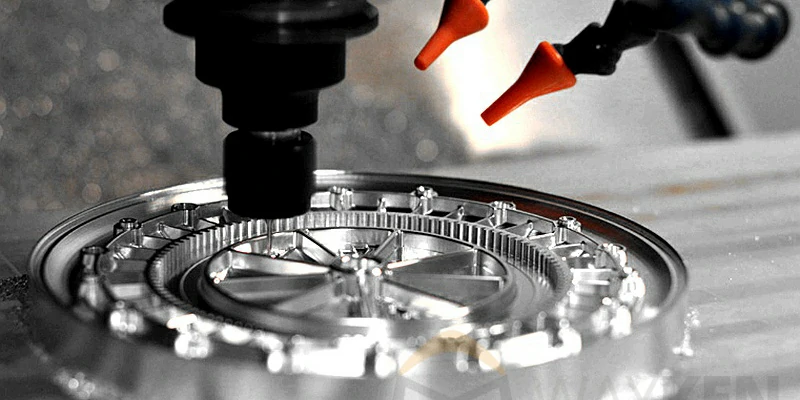

1. Milling: Milling is a common CNC processing method used for aluminum profiles. It involves removing material from the surface using rotary cutters. Milling machines equipped with multiple axes can perform complex cuts and create various shapes with precision. This method is ideal for creating features like slots, pockets, and contours on aluminum profiles.

2. Drilling: Drilling is another widely used processing method in CNC machining. It involves creating precise holes in the aluminum profiles. CNC drilling machines can accurately position the drill bit and control the drilling depth, ensuring consistent hole sizes and positions across multiple profiles. This method is crucial for applications that require fasteners, connectors, or assembly points.

3. Tapping: Tapping is the process of creating internal threads in the aluminum profiles. CNC tapping machines can control the speed and rotation of taps, ensuring accurate thread creation. This method is essential for applications where threaded connections are required, such as assembling frames and structures.

4. Cutting: CNC cutting machines are used to separate aluminum profiles into desired lengths or shapes. These machines can achieve straight, angled, or curved cuts with high precision. CNC cutting is often combined with other processing methods to create finished aluminum profiles ready for assembly or further fabrication.

Conclusion:

CNC processing has become the preferred method for aluminum profile machining due to its numerous advantages. The precision, efficiency, versatility, consistency, and waste reduction offered by CNC processing make it an ideal choice for industries requiring aluminum profiles. Through milling, drilling, tapping, and cutting, CNC machines can create complex and customized profiles with exceptional accuracy and quality. As technology advances, CNC processing will continue to revolutionize the manufacturing industry and shape the future of aluminum profile processing.

.webp)