As a workshop owner or operator, you are constantly looking for ways to improve efficiency, accuracy, and safety in your operations. One area where these factors can be significantly enhanced is in the bending of busbars. Traditionally, manual bending methods have been used, but with the advancement of technology, hydraulic busbar bending machines have become a game-changer in the industry.

Hydraulic busbar bending offers a wide range of benefits that can revolutionize the way busbars are handled and processed in your workshop. From increased productivity to improved precision, the advantages of hydraulic busbar bending are numerous and impactful. In this article, we will explore the various busbar bender benefits of hydraulic busbar bending and why incorporating this technology into your workshop can lead to a more efficient and effective operation.

Enhanced Precision and Accuracy

One of the primary advantages of hydraulic busbar bending is the enhanced precision and accuracy it provides. Hydraulic bending machines are equipped with advanced control systems that allow for precise bending angles and measurements. This level of accuracy is crucial when working with busbars, as even slight deviations can impact the overall quality and functionality of the final product.

By utilizing hydraulic busbar bending machines, workshop operators can ensure that each bend is made with precision and consistency. This not only improves the quality of the finished busbars but also minimizes material waste and rework. The ability to achieve accurate bends consistently is a significant advantage that can set your workshop apart from competitors.

Increased Productivity and Efficiency

Another key benefit of hydraulic busbar bending is the significant increase in productivity and efficiency it offers. Manual bending methods are often time-consuming and labor-intensive, requiring skilled operators to perform each bend accurately. In contrast, hydraulic bending machines can automate the bending process, allowing for faster production times and higher output.

With hydraulic busbar bending machines, operators can quickly and easily set up the machine for different bending requirements, reducing the time spent on each job. This increased efficiency not only allows for faster turnaround times on projects but also enables workshops to take on more jobs and increase overall productivity. By streamlining the bending process, hydraulic busbar bending machines can help your workshop operate more efficiently and effectively.

Versatility and Flexibility

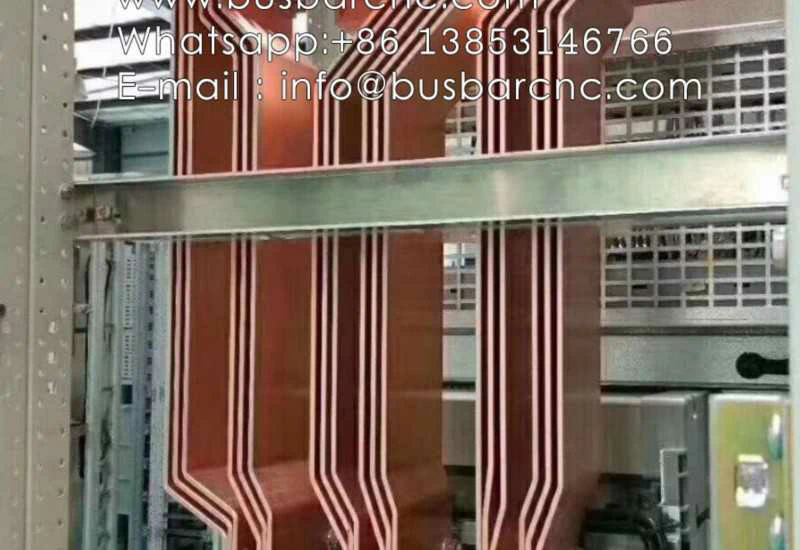

Hydraulic busbar bending machines offer a high level of versatility and flexibility, making them suitable for a wide range of busbar bending applications. These machines can accommodate various busbar sizes and shapes, allowing operators to bend busbars of different materials and thicknesses with ease. This versatility is essential for workshops that work with a diverse range of busbar specifications.

Additionally, hydraulic busbar bending machines can perform a variety of bending operations, including straight bends, offset bends, and U-shaped bends. This flexibility enables workshop operators to meet the specific bending requirements of each project without the need for multiple machines or manual adjustments. The ability to handle various bending tasks with a single machine makes hydraulic busbar bending a cost-effective and practical solution for workshops of all sizes.

Improved Safety and Ergonomics

Safety is a top priority in any workshop environment, and hydraulic busbar bending machines are designed with safety features to protect operators during the bending process. These machines are equipped with safety guards, emergency stop buttons, and interlocking systems to prevent accidents and injuries. By automating the bending process, hydraulic machines also reduce the risk of repetitive strain injuries associated with manual bending methods.

Furthermore, hydraulic busbar bending machines are designed with ergonomics in mind, ensuring that operators can work comfortably and efficiently. The machines are equipped with adjustable height settings, ergonomic controls, and easy-to-use interfaces that minimize operator fatigue and improve workflow. By prioritizing safety and ergonomics, hydraulic busbar bending machines create a safer and more comfortable working environment for workshop operators.

Cost-Effectiveness and Return on Investment

While the initial investment in hydraulic busbar bending machines may seem significant, the long-term cost savings and return on investment make them a worthwhile addition to any workshop. These machines can significantly reduce material waste, rework, and labor costs associated with manual bending methods. By increasing productivity and efficiency, hydraulic busbar bending machines enable workshops to take on more projects and generate higher revenue.

Additionally, the versatility and precision of hydraulic busbar bending machines result in higher-quality finished products, reducing the likelihood of costly errors or defects. The durability and reliability of these machines also contribute to their cost-effectiveness, as they require minimal maintenance and downtime. Over time, the savings and efficiencies gained from using hydraulic busbar bending machines can lead to a significant return on investment for workshop operators.

Conclusion

In conclusion, hydraulic busbar bending offers a multitude of benefits that can transform the way busbars are processed in your workshop. From enhanced precision and accuracy to increased productivity and efficiency, the advantages of hydraulic bending machines are undeniable. By incorporating this technology into your operations, you can streamline the bending process, improve safety and ergonomics, and achieve a higher return on investment.

If you are looking to enhance the efficiency and effectiveness of your workshop, consider investing in hydraulic busbar bending machines. With their versatility, precision, and cost-effectiveness, these machines can help your workshop stay ahead of the competition and meet the demands of your customers. Embrace the benefits of hydraulic busbar bending and elevate your workshop to new heights of success.

https://hmimicro.com/