How to Choose a CNC Processing Factory for Your Prototype Design

When it comes to bringing your prototype design to life, choosing the right CNC processing factory is crucial. With so many options available, it’s essential to consider several factors that will ensure the success of your project. In this article, we will discuss some key points to keep in mind when selecting a CNC processing factory for your own prototype design.

1. Expertise and Experience:

One of the most important factors to consider is the expertise and experience of the CNC processing factory. Look for a company that has a proven track record and specializes in the specific type of prototype design you require. This will ensure that they have the knowledge and skills necessary to deliver high-quality results.

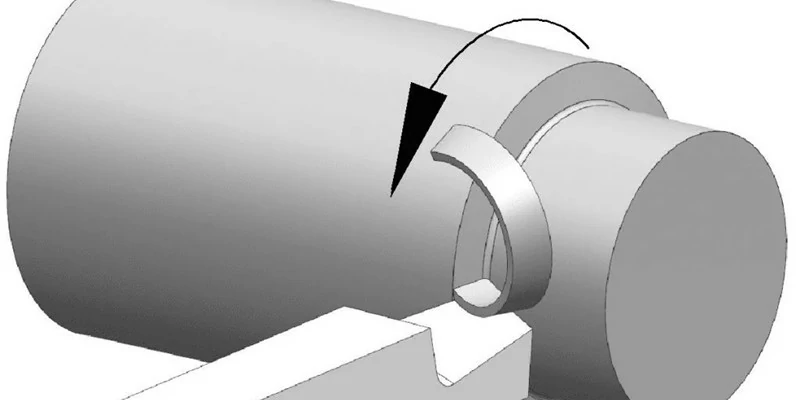

2. Technology and Equipment:

The CNC processing factory you choose should have access to advanced technology and equipment. This will allow for precise and efficient machining, resulting in accurate prototypes. Inquire about the types of machines they use and whether they are up-to-date with the latest industry standards. A well-equipped facility will be better equipped to handle complex designs and produce superior prototypes.

3. Materials and Finishes:

Consider the range of materials and finishes offered by the CNC processing factory. Depending on your prototype design, you may require specific materials such as metals, plastics, or composites. Ensure that the factory can work with your desired materials and provide the desired finishes, such as anodizing, painting, or powder coating. Versatility in material selection will allow for greater flexibility in your design choices.

4. Quality Control:

Quality control is paramount when it comes to CNC machining. Inquire about the quality control processes followed by the factory. Ask if they have certifications or adhere to industry standards such as ISO 9001. A reliable CNC processing factory will have strict quality control measures in place to ensure that each prototype meets the required specifications.

5. Timeframes and Flexibility:

Consider the timeframes and flexibility offered by the CNC processing factory. Discuss your project timeline and ensure that the factory can meet your delivery requirements. Additionally, inquire about their flexibility in accommodating design changes or iterations. A responsive and flexible CNC processing factory will be able to adapt to your evolving needs throughout the prototyping process.

6. Cost and Affordability:

While cost should not be the sole determining factor, it is essential to consider your budget when choosing a CNC processing factory. Compare quotes from different providers and evaluate the value you receive for the price. Keep in mind that low-cost options may not always deliver the desired quality, so strike a balance between affordability and quality.

7. Customer Reviews and Recommendations:

Lastly, research customer reviews and seek recommendations from others who have utilized the services of the CNC processing factory. Online platforms and forums can provide valuable insights into the experiences of past clients. Positive reviews and recommendations indicate a reliable and reputable CNC processing factory.

In conclusion, selecting the right CNC processing factory for your prototype design requires careful consideration. Prioritize expertise, technology, materials, quality control, timeframes, cost, and customer reviews when making your decision. Taking these factors into account will increase the chances of a successful partnership and the realization of your prototype design vision.