The Latest High-Gloss Aluminum Parts: A Synthesis of Sophistication

In the ever-evolving landscape of manufacturing, one trend that continues to captivate the industry is the use of high-gloss aluminum parts. Renowned for their sleek and modern appearance, these parts have become a popular choice for a wide range of applications, including automotive, aerospace, and consumer electronics.

To meet the growing demand for high-quality aluminum parts, innovative techniques have been developed to enhance their visual appeal and durability. One such technique involves applying a black primer followed by laser engraving and UV oil coating. This combination not only enhances the aesthetics of the parts but also provides them with added protection against wear and tear.

The process begins with the application of a black primer. This step serves as a base coat, providing a uniform and smooth surface for subsequent treatments. The primer also helps to facilitate the adhesion of other coatings, ensuring a long-lasting finish.

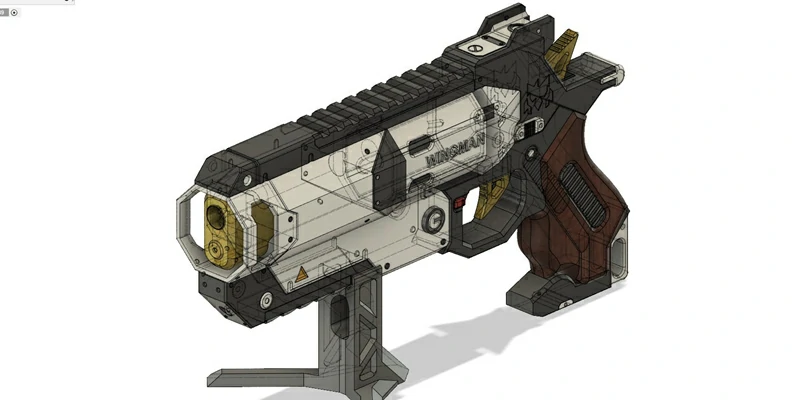

Once the primer has dried, laser engraving is employed to create intricate and precise designs on the aluminum surface. With the use of advanced laser technology, complex patterns, logos, or text can be engraved onto the parts, adding a personalized touch or branding element to the finished product. This customization option has made high-gloss aluminum parts a preferred choice for industries seeking to establish a unique identity.

After engraving, the parts are coated with a layer of UV oil. This final step not only adds an impeccable glossy finish to the surface but also provides protection against scratches, corrosion, and fading due to sunlight exposure. The UV oil coating acts as a shield, preserving the visual appeal of the parts and ensuring their longevity in various environments.

The advantages of utilizing high-gloss aluminum parts extend beyond their aesthetic appeal. The lightweight nature of aluminum makes these parts ideal for industries where weight reduction is crucial, such as the automotive and aerospace sectors. Furthermore, aluminum possesses excellent thermal conductivity, making it an excellent choice for heat dissipation in electronic devices.

In addition to their functional attributes, high-gloss aluminum parts also offer environmental benefits. Aluminum is highly recyclable, with the ability to be recycled and reused countless times without compromising its properties. This recyclability contributes to reducing the carbon footprint associated with manufacturing processes and promotes sustainability in the industry.

As the demand for high-gloss aluminum parts continues to grow, manufacturers are constantly exploring innovative techniques and technologies to further enhance their quality. Advancements in surface treatment processes, such as the combination of black primer, laser engraving, and UV oil coating, are a testament to the industry’s commitment to delivering exceptional products.

In conclusion, the latest high-gloss aluminum parts with black primer, laser engraving, and UV oil coating represent a synthesis of sophistication in the manufacturing realm. These parts not only exhibit a striking visual appeal but also offer durability, customization options, and environmental benefits. As industries across the globe strive for excellence, the utilization of high-gloss aluminum parts serves as a testament to the relentless pursuit of innovation and quality.

.webp)