The world’s lightest solid material – graphene aerogel

Graphene, known as a wonder material, has taken the scientific and engineering communities by storm. With its remarkable properties, such as being the thinnest and strongest material ever discovered, it has revolutionized various industries. One of the most exciting advancements in graphene technology is the creation of graphene aerogel, which is hailed as the world’s lightest solid material.

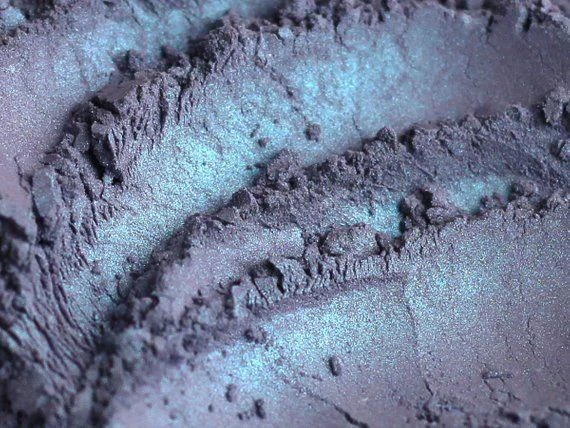

Graphene aerogel is an ultra-lightweight material composed of a three-dimensional network of interconnected graphene sheets. It is formed through a process called gelation, where a graphene oxide solution is mixed with a liquid, usually water or alcohol, and then freeze-dried to remove the liquid component. This results in a solid structure that retains the graphene’s unique properties while being incredibly light and porous.

The density of graphene aerogel is astonishingly low, with some formulations having a density less than that of air. This means that it is lighter than any other solid material known to humankind. To put it into perspective, imagine holding a cubic centimeter of graphene aerogel in your hand. Despite its solid appearance, it would feel almost weightless, giving the impression of holding nothing at all.

Yet, despite its minimal weight, graphene aerogel possesses exceptional strength and mechanical properties. Due to the strong covalent bonding between the carbon atoms in the graphene sheets, it exhibits great tensile strength, making it resistant to deformation or breakage. Its high flexibility also allows it to withstand immense pressures without losing its structural integrity. This combination of lightweight and strength makes graphene aerogel a promising candidate for various applications.

One area where graphene aerogel shows significant potential is in energy storage and conversion. Its unique structure and high surface area enable efficient ion transportation, making it an ideal material for supercapacitors. Supercapacitors store and release energy much faster than traditional batteries, making them crucial for technologies such as electric vehicles and renewable energy systems. Graphene aerogel’s lightweight nature also makes it appealing for aerospace applications, where reducing weight is critical to improving fuel efficiency.

Furthermore, graphene aerogel has excellent thermal insulation properties. It can effectively prevent heat transfer due to its low thermal conductivity. This makes it suitable for applications in insulation materials, such as in buildings or electronic devices, where minimizing heat loss or gain is desirable. The material’s porous structure also allows for efficient absorption of gases and liquids, opening up possibilities in areas like pollutant capture and water purification.

While graphene aerogel holds tremendous promise, there are still challenges to overcome before it becomes widely adopted. One significant obstacle is the cost of production. Currently, the manufacturing processes for graphene aerogel are complex and expensive. Researchers are actively exploring more cost-effective methods to scale up production and make it commercially viable.

In conclusion, graphene aerogel represents a groundbreaking development in material science. Its exceptional lightweight, combined with its strength and unique properties, opens up a world of possibilities for numerous industries. As advancements continue and production costs decrease, we can anticipate graphene aerogel playing a pivotal role in shaping our future, from energy storage to insulation and beyond. The potential applications seem endless, making graphene aerogel a material worth watching closely in the years to come.